Originally written for The Radavist.

Editing the photos from my visit to Baum Cycles this February, an eerie feeling came over me. I knew it’d been some time since I last took photos with the ‘big camera’ at 7 Seabright St, North Shore. For some reason, it felt like a precise period of time. My suspicion was confirmed. 10 years.

Perhaps this creeping sense was due to the fast-approaching Handmade Bicycle Show Australia, 3-5 June 2022, which has blossomed hugely from the seed I (FYXO) planted in 2012. I’d met Darren nearly another 10 years prior at Jesse of Geisler Cycles’ workshop. Polar to my extroverted self, Darren kindly gave me a brochure of his frames – handmade steel, themed on coffees as it would be. Ristretto, Cortado, Cappuccino! I remember thinking no one is going to buy a frame called a cappuccino, the milky novelty beverage of the coffee world. It sat at the bottom of the tiers, deservedly, but to this day the Corretto remains at the top.

During that visit in 2012, I took John (Watson), blogger of the increasingly popular ‘Prolly Is Not Probably’ – Pre-The Radavist – as I felt that the two should definitely meet. To say a lot has changed for all three of us since is an understatement.

For me, walking through a factory is filled with nostalgia. I grew up in a factory. My Grandfather was a metallurgist, who made furnaces, custom wire drawing machines, and was always at the lathe, or behind the shield of a welding mask. He insisted that I wore a motorbike helmet IN the factory to avoid the very thing that occurred the day I didn’t – splitting my head open on the long sharp arms of the guillotine. When I walk through the Baum Factory, all the machines feel familiar, the smell of lubricants delicious, the swarf on the floor a sensory delight, right down to the familiar feel of the lunchroom. It’s better than a chocolate factory and I don’t have to wear a dorky helmet!

The overwhelming sense you get at Baum Cycles is precision in pursuit of perfection. At the ripe age of 25 years strong, this analogy is fitting for many builders in the custom world – but it is the precision at scale that Baum truly obsesses about.

The team at Baum Cycles work away calmly as we waltz clockwise around the factory. Aaron monitors the mill as it runs through lines of program.

Between butting titanium tubes, Daryl shows me photos from his phone of his latest acquisitions. His two-wheeled collection is in Greg Softley territory, and I hope to get an invite to his ‘bike bunker’ one day.

Darren’s mind and our conversations are always hectic covering topics from manufacturing processes, industry trends, butting and tube selection, to his chooks who roam the factory floor, his boys, and the new oven at home. Passionate on each subject with equally expansive knowledge.

As we walk around the manufacturing side of the process, for every step of the process there is a why and a how. Like having matching machines, with identical setups so you don’t need to ‘recalibrate your brain and hand movement’ based on the machine used for a given process. Deliberate choices made to minimise the possibility for error. A worthy investment.

We wander past Darren’s 18th birthday present – a surface table. A precision instrument, perfectly flat for referencing a frame along its journey to completion. Bemused by the seeming unusual request to mark his entry to adulthood his Dad said ‘I think I know a guy’. They drove to a Whelan the Wrecker of sorts, and sure enough amongst his second-hand oddities and building materials was this very heavy steel table. ‘$50 and you can have it’. Truly a steal of an investment.

This little knick knack was a task set of the class at trade school. Two pieces of steel that fit within each other – perfectly. Darren made the task deliberately more challenging and the result more satisfying.

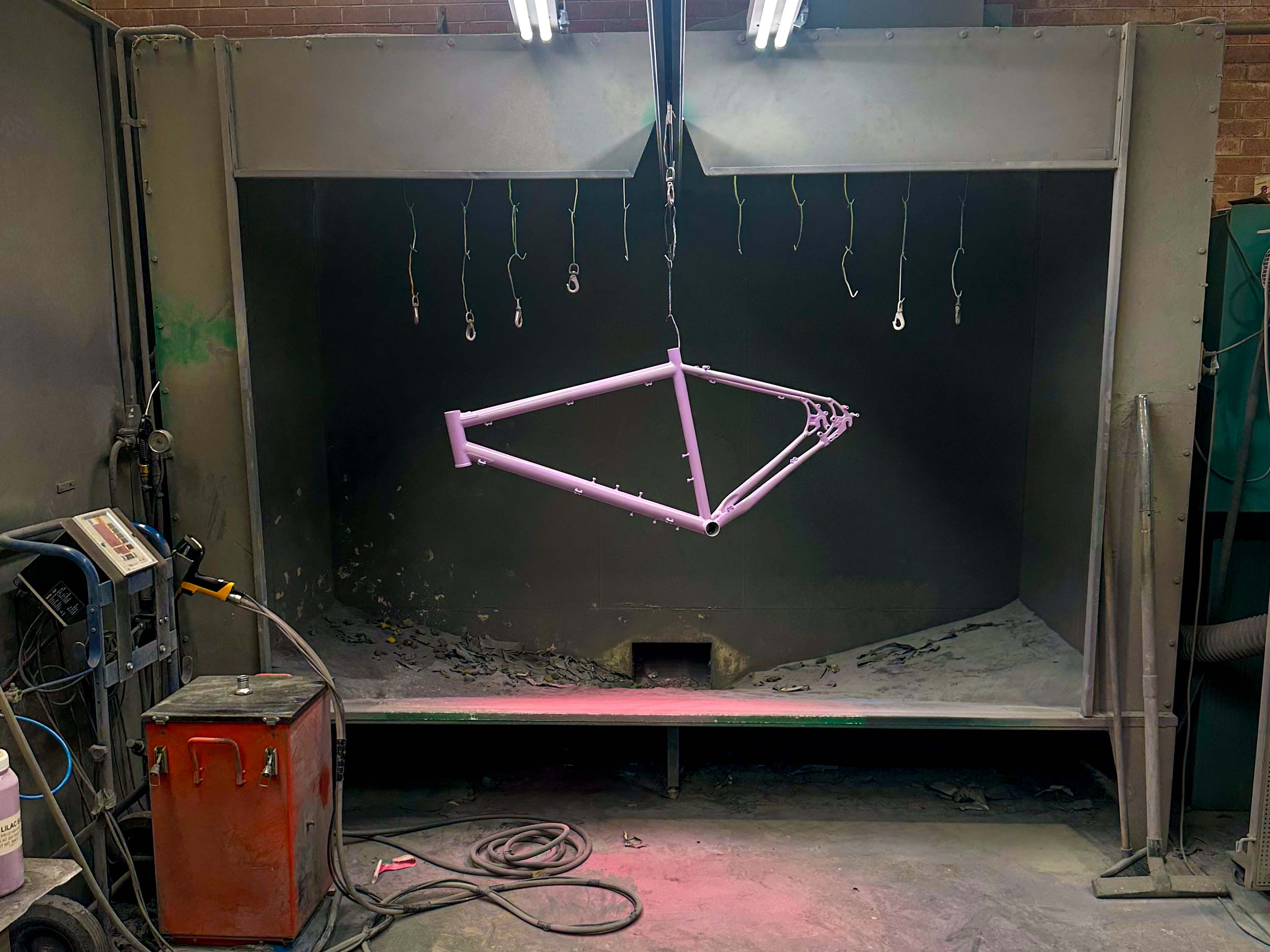

Striving for perfection has been the constant thread and is evident in each naked frame.

Precision means owning some VERY nice instruments of measure.

Michael prepares chains for waxing between emails and phone calls and Chris – who has been in the Baum family since my first visit, is like an Iron Chef, head down, quietly assembling and plating before crossing the pass. Another perfect dish ready for the customer.

A common response when talking of ‘Baum’s’ is why are they so expensive? A large component of what the team does is educate people on this, or as Darren explains it – why is everyone else so cheap? This was an internal conversation Darren had before he embarked on frame building as a career. At the time, no local manufacturer was producing a frame that retailed even close to a Colnago. Why? Similar tubesets, construction methods, how could you possibly survive, let alone thrive with such a pricing strucure. From 2006 onwards, a Baum frameset has cost more than a Colnago, justifiably so.

It’s a deeper conversation of Darren’s passionate support of local manufacturing and the frame building world that needs education in the absence of government support. As we have seen in Australia, once the government stopped subsidising the car industry, manufacture went overseas.

A segway – I called him back to ask about his Bike Fit, which is performed by Dr. Dominic Briscomb of Woodend Osteopathy as Darren explains ‘because you shouldn’t take medical advice from a welder’. Dominic’s addition to the team is particularly heart warming to me as he’s the only person I’ve had / taken fitting advice from as we also have a friendship born out of racing bikes that started on the infamous Hell Ride.

When I picked up the phone to verify a detail for this story I told Darren ‘my 2 minute egg-timer is on’ – 40 mins later I’m glad I ignored it as these two nuggets came out of that chat.

Another Melbourne identity, who has been present in Baum frames for the past two decades is Raoul Luescher of Luescher Teknik. The work is hidden from view – a carbon sleeve bonded to the inside of the seat tube to ensure an interface for the seatpost without risk of crimping or cracking. A process that evolved from issues with failing Campagnolo Record Titanium posts.

Baum’s original location was in North Melbourne, in close proximity to the Bicycle Hospital, and the original Crumpler workshop. This was the natural habitat for bike couriers who would discard their broken alloy frames out back, punished from life on the road or from crashes in an alleycat. Darren asked if he could autopsy the frames to examine where and why they failed to develop his understanding of materials. Darren has also picked my own brain about fixed gear and physiology as he was ‘working on something’ and knew I’d spent hours on the road pedalling one, specifically back pedalling one.

Any conversation with Darren makes you feel ‘smarter’ about the world of bikes. A lifetime of riding, racing, manufacturing and managing a small business is something he is generous to share – with passion and precision.

Eddy Merckx Pista - Sweet Dreams

Marin Gravel ebike for commuting - Quick Charge!